In today’s manufacturing environment, controlling who enters your facility is more critical than ever. Large factories and production sites bustle with employees, contractors, suppliers, and visitors, and every person who steps through the door can pose a potential security risk or compliance concern.

High-profile data breaches, intellectual property theft, and safety incidents have drawn attention to secure visitor flows in manufacturing. The global market for visitor management solutions is expanding rapidly, valued at around $1.7 billion in 2024 and projected to grow at double-digit rates—a sign that businesses are embracing smarter ways to manage visitors.

This is where a modern visitor management system for manufacturing comes into play. It digitizes the visitor check-in process, ensuring only authorized individuals gain access to the right areas of your plant. This post explains why a visitor management system (VMS) is essential for manufacturing facilities and how the right solution can strengthen your security and compliance posture.

See how friendlyway can transform your visitor experience—while protecting your people, property, and reputation.

Why Manufacturers Need a Visitor Management System

Manufacturing sites face unique challenges, from safeguarding trade secrets on the production line to protecting workers on a factory floor full of heavy machinery. Here’s why implementing visitor management for manufacturing facilities is essential.

Protecting intellectual property and trade secrets

Factories often house proprietary processes and designs. A VMS ensures that only approved visitors and employees can enter sensitive areas. Screening and credentialing guests reduces the risk of espionage or theft of confidential information.

For instance, a digital VMS can automatically flag unauthorized visitors or unusual visit requests, helping prevent breaches before they happen.

Ensuring workforce safety and facility security

Unauthorized or unsupervised visitors on the shop floor can lead to accidents or disruptions. A VMS verifies visitors’ purpose and access permissions, maintaining a safe environment.

Visitors can be required to view safety instructions or don personal protective equipment during check-in, ensuring they don’t become a hazard to themselves or others. In this way, the system helps keep everyone on site safe and accounted for.

Maintaining regulatory compliance

Manufacturing businesses must adhere to regulations (from OSHA safety rules to industry-specific standards—more on that later), and managing facility access is often a compliance requirement.

A VMS offers detailed logs of entries/exits and can enforce compliance steps (like NDA signing or safety briefings) during check-in. This keeps you compliant and provides an audit trail if regulators come knocking.

Increasing operational efficiency

Beyond security, a modern VMS streamlines the visitor process, improving your overall efficiency. Automated self-check-in kiosks, pre-registration capability, and instant badge printing mean less waiting time and less burden on your front desk staff.

Your reception team no longer needs to manage paper logbooks or manually notify hosts—the system handles everything. This efficiency in a busy manufacturing facility keeps operations running smoothly with minimal interruption.

In short, a visitor management system for manufacturing facilities protects your people, intellectual property, and productivity. Forward-thinking manufacturers are adopting advanced solutions (such as friendlyway Visitor Management) to meet these challenges and build a safer, effective operation.

Compliance and Regulatory Drivers

Regulatory compliance is a central driver for visitor management in manufacturing. Failure to comply with laws can lead to hefty fines or even shutdowns. Implementing visitor management for manufacturing facilities addresses many requirements by ensuring control and transparency. Critical compliance drivers include:

OSHA and safety protocols

The Occupational Safety and Health Administration (OSHA) demands a safe environment for everyone, including visitors. VMS platforms ensure each guest is briefed on safety rules and accounted for during emergencies.

ITAR and export control

In compliance with the International Traffic in Arms Regulations (ITAR), facilities handling defense-related products must control access by nationality and clearance. A VMS verifies visitor identity and eligibility, preventing exposure to sensitive data.

GMP and product safety

Pharmaceutical and food manufacturers must guard against contamination. VMS tools enforce hygiene declarations and restrict access to clean zones, supporting Good Manufacturing Practice (GMP) standards.

Data privacy laws (CCPA/GDPR)

The California Consumer Privacy Act (CCPA) and Europe’s General Data Protection Regulation (GDPR) also apply to visitor records. A VMS collects data with consent, allows for data removal, and ensures secure storage.

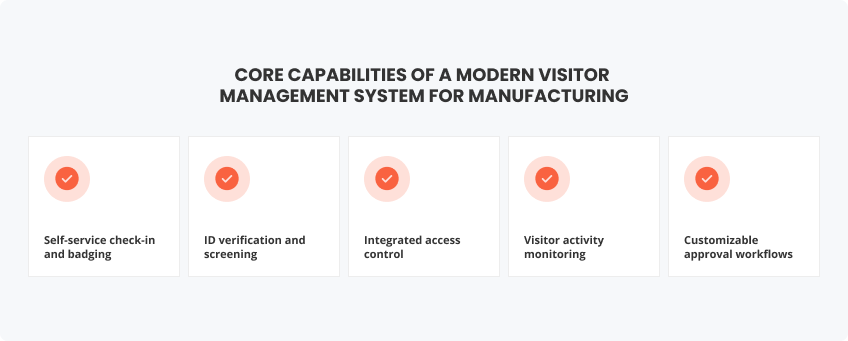

Core Capabilities of a Modern VMS in Manufacturing

A good visitor management system for manufacturing comes packed with features designed to protect facilities like factories and plants and deliver compliance and efficiency benefits. Let’s look at some capabilities you should expect and how they help your operation.

Visitor check-in and badging

A VMS optimizes the visitor experience and ensures compliance steps are not overlooked. Self-service kiosks or tablet stations in the lobby allow visitors to check in, sign documents, and print temporary ID badges independently, reducing bottlenecks during shift changes or large group visits.

Identity verification and watchlist screening

Modern visitor management software can scan IDs, take photos, and cross-check visitors against internal watchlists or external databases. It also helps prevent previously terminated individuals from gaining access. In high-security manufacturing sectors, such screening is invaluable for peace of mind.

Integration with physical security infrastructure

A VMS can tie into turnstiles or door locks to manage access points. It can grant or restrict entry to specific areas based on visitors’ credentials as they check in and receive a badge or QR code. This ensures that only approved guests can enter sensitive zones like R&D labs or production lines.

Entry/exit tracking and activity monitoring

Security teams get real-time dashboards displaying who is on-site and where, improving situational awareness. The system can immediately alert employees if someone without proper clearance tries to tailgate through a secure door. By merging digital logs with physical access control, manufacturers create a tightly guarded facility where every entry is tracked.

Customizable workflows

A good VMS is configurable with custom visitor policies and approval workflows. For example:

- A first-time vendor must watch a safety orientation video and answer a few questions.

- A recurring delivery driver merely scans a QR code to log their arrival.

Tailoring check-in flows to various visitor types allows you to cover all necessary compliance bases.

The benefits of these features become evident very quickly. Automation and consistency mean fewer mistakes and lower costs. A VMS effectively performs the roles of a receptionist and security guard combined, which can cut significant overhead.

Other Key Features for Secure Manufacturing Facilities

To support secure operations, a VMS must deliver industrial-grade functionality:

- Pre-registration. Visitors can register online before arrival. Hosts approve visits in advance, and the system pre-screens data for red flags, saving time at check-in.

- Zone-based access control. Manufacturing facilities often have multiple zones. VMS tools assign visitor rights and sync with door systems to control movement.

- Unauthorized entry alerts. Instant notifications for unauthorized attempts to enter the location trigger immediate response and action at manufacturing sites.

- Digital document signing. Visitors can sign NDAs, safety waivers, or compliance forms directly at the kiosk. The system stores these for future audits and legal protection.

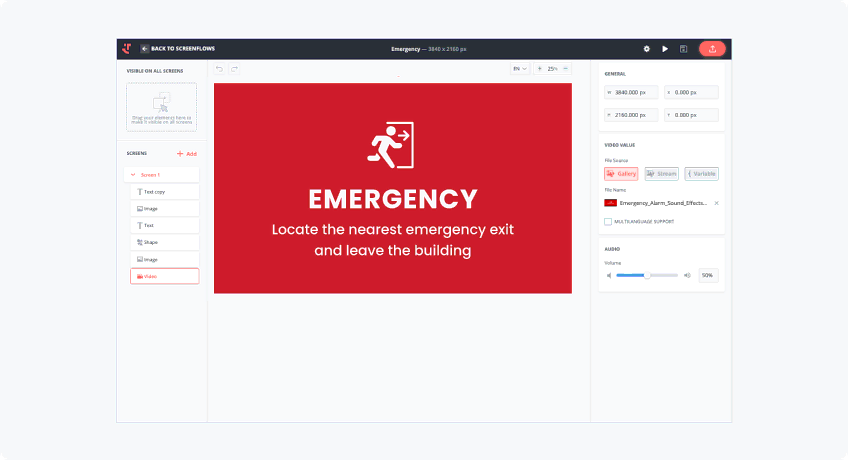

- Emergency evacuation support. In emergencies, a VMS locates guests and employees still on-site. It generates real-time evacuation lists and can send alerts to visitors’ phones.

friendlyway Cloud Platform combines visitor management with digital signage capabilities.

Implementing Your VMS Successfully

A bit of planning goes a long way to get the most out of a VMS in a manufacturing environment.

1. Clearly define your visitor policies and approval workflows.

Decide which visitor types require additional screening or escorts (for example, contractors going into high-risk areas) and what information must be collected from each person. By setting these rules upfront, you can configure the VMS to enforce them automatically and ensure consistency across the board.

2. Train your staff and front-desk team on the new system.

Security personnel should know how to use the dashboard, run reports, and respond to alerts from the VMS. Likewise, receptionists or lobby attendants should feel comfortable guiding visitors through the self-check-in if needed. A brief training session and hands-on practice will build confidence that the system is being used correctly. Also, regularly test scenarios to ensure your team stays sharp.

3. Periodically audit your visitor management process.

Use the reporting features to see if there are any gaps—for instance, are some visitors bypassing the system, or are certain procedures being skipped during busy periods? The insights from these reports can help you adjust the workflow or provide refresher training to staff, ensuring visitor management remains tight and effective as your facility grows or regulations change.

Why Choose friendlyway for Manufacturing Visitor Management?

friendlyway delivers an end-to-end visitor management solution tailored to manufacturing facilities. It combines a software platform with custom workflows and badge-printing self-service kiosks into one system.

Our solution supports pre-registration, ID checks, zone-based access, and digital document signing. With access to an experienced team of software developers and hardware integration partners, we help manufacturers control access, enforce safety, and meet compliance requirements across multi-site operations 24/7.

Whether you need a standalone solution or integration into a broader building management system, we deliver. The visitor management solution can even be expanded to include centralized staffing management and other capabilities, as was the case at one of our clients, a large light industrial manufacturer in the US.

Secure Your Facility—and See It in Action

In manufacturing, you can’t afford to leave security and compliance to chance. A modern visitor management system is a powerful ally for manufacturing facilities, providing efficient lobby management.

It safeguards your people and property while easing the burden of regulatory compliance. In short, it lets you focus on productivity, knowing that every visitor is accounted for and every rule is followed.

Don’t wait for a security breach or a failed audit to make a change—take a proactive step now.