Manufacturers today face mounting pressures to bolster security and comply with stringent regulations around workplace safety and data protection. A visitor management system (VMS) can significantly enhance security and compliance for manufacturing facilities by digitizing the check-in process and ensuring only authorized people gain access.

Read on to learn more about how to improve your security and compliance with the help of modern visitor management in manufacturing.

Why Visitor Management Matters in Manufacturing Environments

Manufacturing companies in the U.S. operate under specific security and regulatory pressures, especially in critical infrastructure sectors like defense, energy, and pharmaceuticals. They must comply with laws that protect public safety and national security.

Allowing guests or contractors to roam a production facility without proper tracking or supervision can lead to serious risks. Safety hazards are a primary concern: an untrained visitor on a shop floor full of forklifts and industrial equipment could inadvertently end up in a dangerous area and suffer an injury, or cause an accident that harms employees.

Another major risk is intellectual property (IP) theft or industrial espionage. Trade secrets, product designs, and proprietary processes can be compromised if a malicious actor gains entry by posing as a visitor. Untracked visitors also pose physical security threats ranging from theft and vandalism to violence.

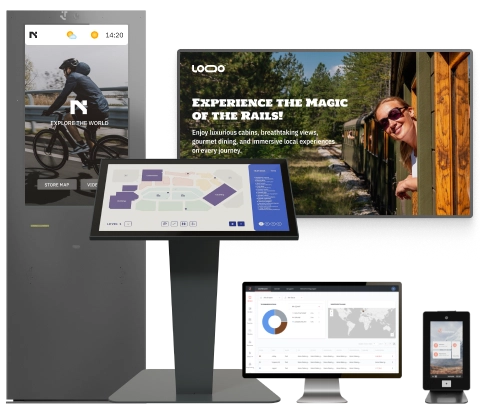

Industrial workplace solutions by friendlyway are designed to enhance communication, boost productivity, and ensure safety across your facility.

Challenges in Traditional Visitor Registration

Despite these risks, many manufacturing facilities still rely on old-fashioned visitor sign-in methods, creating significant security breaches. Paper logs at front desks can be easily bypassed, allowing unauthorized access without immediate detection. There’s often no way to verify identity — a determined intruder could simply walk in without signing, or tailgate behind someone else, and there may be no immediate alert or barrier to stop them.

Other challenges with manual visitor logs include the lack of real-time visibility. A paper log can’t show you at a glance who is currently in the facility or flag if someone has overstayed their authorized time. If an emergency evacuation is needed, safety officers must grab the binder and try to account for people, which wastes precious minutes.

Reliance on manual compliance documentation further burdens administrative staff with tedious paperwork and inefficient record-keeping. Paper records present major challenges during audits and inspections, including deciphering handwriting and verifying visitor approvals.

Benefits of a Digital Visitor Management System in Manufacturing

A modern digital visitor management system directly addresses the above challenges, offering a range of benefits tailored to manufacturing environments:

- Controlled and monitored facility access: A manufacturing site visitor registration system ensures that only authorized guests enter the premises and only into approved areas.

- Real-time guest identification and status tracking: With a digital system, facility managers gain real-time visibility into everyone on site.

- Regulatory compliance (ISO, OSHA, and site-specific rules): Digital visitor management greatly simplifies compliance with standards like OSHA workplace safety rules, ISO certifications, and industry-specific regulations.

- Improved third-party onboarding and contractor management solution: Manufacturing facilities often deal with large volumes of contractors, vendors, and truck drivers coming in for deliveries, maintenance, or short-term projects.

- Faster emergency response with accurate headcounts: By automating headcounts and notifications, a digital check-in system for industrial facilities reduces confusion in chaotic situations and ensures that no guest is overlooked when it matters most.

Industry-Specific Use Cases

Different manufacturing sectors have unique needs and use cases for visitor management. Let’s explore a few scenarios across industries.

High-security manufacturing

Facilities that produce defense or high-tech electronics operate under the highest security scrutiny. In these environments, a VMS is essential to enforce strict clearance checks for every visitor.

Think of a semiconductor fabrication plant working on cutting-edge chips — they might use a VMS to ensure that competitors’ personnel never set foot in the facility, and that every visitor signs a robust NDA and safety agreement digitally before viewing the production line.

Food and pharmaceutical production

Food processing plants and pharmaceutical manufacturers have stringent hygiene and contamination controls. For these industries, visitor management is tied closely to Good Manufacturing Practices (GMP) and food safety regulations.

In a large food factory, a VMS can present a hygiene briefing video and a questionnaire at check-in, covering hairnet use, hand washing, forbidden items (no jewelry, no outside food), and so on. Personal Protective Equipment (PPE) compliance is another facet: in a pharma lab, every visitor might need to wear a lab coat, booties, and safety glasses. A visitor kiosk can remind them of required PPE, and not complete the check-in until they acknowledge this.

Ensure security and compliance with friendlyway contingent workforce management solutions.

Chemical and energy facilities

At a chemical plant, a VMS can require visitors to watch a safety briefing about hazard communication (e.g., understanding the meaning of various alarm sirens and chemical hazard labels) and emergency evacuation routes.

On the security side, these sites worry about sabotage and terrorism as well. The VMS might tie into a broader Physical Identity and Access Management (PIAM) system that coordinates with background checks like the Chemical Facility Anti-Terrorism Standards (CFATS) vetting for certain high-risk chemical workers.

Automotive and logistics plants

Automotive factories and large logistics hubs have a constant flow of third-party visitors. Truck drivers arrive with deliveries, vendors come for equipment maintenance, and contractors may be on site for construction or installation projects.

With a contractor check-in factory system, a trucking company can pre-register all its drivers in the system; when a driver arrives at an automotive assembly plant, they might simply scan their license or an assigned QR code at an outdoor kiosk and print a temporary badge. For a busy logistics warehouse, the VMS can be integrated with the ERP or scheduling system to correlate purchase orders or delivery appointments with visitor entries.

Key Features of Manufacturing-Ready Visitor Systems

When evaluating a visitor management system for a production environment, certain features are especially important to ensure it can handle the complexities of manufacturing facilities. Key features to look for include:

- Pre-registration for contractors and vendors: The system should allow hosts or security to pre-register visitors before they arrive. This means entering their details (name, company, visit purpose, date/time) into the system or sending the visitor a link to fill in their information and upload IDs ahead of time.

- Digital NDAs and safety briefing workflows: A manufacturing-ready VMS will include the ability to present documents and forms to visitors during check-in.

- Badge printing and zone-based plant access control software: Upon sign-in, the system should print a professional visitor badge that includes the person’s name, photo (if captured), their host or department, the date, and an expiration time.

- Audit-ready visitor logs and time-stamped visitor records: Any robust VMS will maintain a comprehensive log of visitor activity. This includes time stamps for check-in and check-out, the host name, reason for visit, and any documents signed or assets issued (like a loaner badge or PPE kit).

- Kiosk check-in with PPE compliance confirmation: Manufacturing plants often mandate specific PPE for anyone on the floor. A manufacturing-ready VMS typically offers self-service kiosk stations at entry points where visitors not only sign in but also go through a checklist related to PPE and safety.

Integration and Deployment

Implementing a visitor management solution in manufacturing involves considerations beyond just features — how the system will integrate with existing infrastructure and how to roll it out across potentially multiple facilities. A top-notch VMS for manufacturing should be able to link with ERP, HR, or industrial site security systems.

When it comes to deployment, companies must decide between cloud-based and on-premises solutions. A cloud-based VMS offers easy scalability, remote access to the data, and typically faster deployment since the vendor handles the IT infrastructure. An on-premise system keeps all data and servers within the company’s network.

Rolling out a VMS to multiple sites requires planning. This is where the ability to standardize workflows but also allow site-specific rules comes into play. For example, corporate policy might dictate that every visitor signs a general NDA, but a particular site adds an extra safety or language support form.

Another integration aspect is compliance reporting. A VMS should help with regulatory record-keeping automatically, but it’s wise to ensure it aligns with frameworks you follow. For instance, if you operate in the EU, the system should have features to support GDPR compliance (data encryption, consent capture, data retention settings).

Lastly, consider hardware deployment. In an industrial environment, you may need ruggedized kiosks or tablets at entry points that can withstand harsh conditions (dust, temperature), or you might use standard lobby kiosks if the check-in happens in an office area.

Streamline your visitor management processes with the industry’s best-in-class cloud solution.

Conclusion

A modern VMS provides a professional, automated way to welcome and track visitors, vendors, and contractors without compromising safety or productivity. Implementing a VMS is a relatively simple step that can pay big dividends: from preventing potential security incidents, to impressing customers and auditors with a cutting-edge process, to responding more effectively in emergencies.

It’s an investment not just in convenience, but in the long-term resilience and reputation of the business. Digital check-in and smart factory access technology have truly become integral to the secure factory of the future.

FAQ

Key compliance standards include EHS compliance system, PPE compliance check, OSHA safety regulations, and ISO certifications like ISO 45001 for safety (which covers protecting visitors) and ISO 27001 for visitor tracking (which requires controlling physical access to systems).

Food and pharma companies can meet FDA FSMA or GMP requirements by logging that visitors received hygiene and allergen training. Modern VMS platforms often comply with privacy laws like GDPR or CCPA — they secure visitor data and allow consent capture and data removal as needed.

Yes. Most enterprise-grade VMS solutions offer integration with physical access control systems and on-site hardware.

For managing many contractors at once, a few strategies are typically used. First, pre-register and pre-screen contractors in bulk. Second, you can deploy multiple check-in stations or kiosks to process several people simultaneously — the data all feeds into the central system, so you maintain oversight. Third, for frequent contractors, many systems allow creation of profiles or credentials that persist.

Absolutely. One of the critical advantages of a digital VMS is during emergencies. Since the system knows who is on-site (visitors and often contractors/employees if integrated), it can generate a real-time evacuation list at the push of a button. A VMS can send evacuation alerts to visitors’ cell phones (since the system often collects contact info during sign-in).

Yes, most modern visitor management platforms are highly configurable to align with your specific safety protocols and workflow. You can tailor visitor types and rules.