In a manufacturing facility, constant control over the flow of all visitors, including contractors, vendors, auditors, or clients, is critical for security. If an untrained visitor gets access to the shop floor, they could step into a potentially hazardous area with forklifts or machinery and cause an accident that harms employees.

Despite the risk, plenty of manufacturers still rely on old-fashioned manual visitor management systems (VMS) such as paper sign-in sheets or spreadsheets. In this article, we will examine visitor management challenges in manufacturing, their impact on safety, and modern solutions that improve manufacturing facility security and compliance.

Streamline your visitor management processes with friendlyway.

Key Challenges in Visitor Management for Manufacturing

Companies have to deal with several persistent obstacles in on-site industrial visitor management, such as:

Manual check-in processes

If you still rely on slow and error-prone manual sign-in with pen and paper, you will create bottlenecks at entry points and extra work for staff. These processes are antiquated, as they fail to provide accurate and up-to-date information. Often, front desk personnel have to re-enter data or decipher illegible handwriting, and guests may wait longer to be processed, which results in a delay of their business.

Lack of real-time visibility

With a paper logbook, it’s impossible to know at a glance who is currently in the facility and their specific location. In case your guests overstay their authorized time or stray into the wrong area, paper logs won’t flag it. This lack of real-time tracking means that during an emergency like a fire or evacuation, staff might have to grab a sign-in binder and attempt to account for the guests manually, wasting precious minutes. This visibility gap will hinder prompt emergency response and can cost lives.

Determined individuals can easily bypass an outdated visit process. Paper logs at the front desk can be easily skipped or fooled, as people can tailgate behind an employee or walk in without signing the sheet. Often, there is no way to verify a visitor’s identity or check them against watch lists with the help of a manual log. This opens the door for unapproved malicious visitors who want to enter sensitive production areas, potentially leading to theft, vandalism, or even workplace violence.

Compliance issues

Manufacturers have to obey strict safety and security regulations. OSHA guidelines recommend established sign-in/out procedures and detailed records as part of workplace safety programs. Many industry standards and certifications (such as ISO 45001 for safety or ISO 9001 for quality management) require controlling access to the site and maintaining records of non-employees at the facility. Without proper systems in place, manufacturing visitor compliance becomes difficult to achieve.

Difficulty in managing multiple entry points

Manufacturing plants often comprise large and complex territories with multiple entrances, and, in many cases, multiple sites or campuses. Without standard policies and linked systems, manufacturers risk visitors slipping through cracks – one location may allow access that wouldn’t be permitted at another. These discrepancies can cause security breaches across the facilities.

The Impact of Ineffective Visitor Management

If you handle visitor management poorly, the fallout can affect many aspects of the manufacturing operation.

Operational disruptions and productivity loss

Cumbersome check-in procedures create unnecessary delays that disrupt the flow of critical operations. For example, if a contractor has to wait in line to sign a paper log, it will delay deliveries or maintenance work. Front-desk specialists spend extra time on manual visitor management and correcting log errors, which reduces the time available for their core duties. So, when visitor management isn’t streamlined, it can slow down business.

Increased risk of safety incidents

Unmanaged guests can create situations that lead to safety hazards and equipment damage. When they are unfamiliar with the facility’s safety protocols and enter a restricted area, such as a welding zone or chemical storage, it could lead to an injury or cause an accident. There have been cases where guests have triggered machinery or walked into forklift paths, putting themselves in danger.

Challenges in emergency evacuations

Without a reliable way to track your guests, it’s difficult to rescue them during an emergency, as security staff may struggle to identify and account for every visitor in time. In case of chaotic situations, it would be impossible to find all the people who are inside and contact them. This can be life-threatening, as according to the Occupational Safety and Health Administration (OSHA), treatment for a serious injury should begin within just three to four minutes of an accident. Any delay could make the difference in a rescue.

Negative impression on clients and partners

An outdated visitor management approach can negatively impact the manufacturing company’s image. Let’s imagine an important client arrives at a facility only to face a disorganized sign-in process: fumbling with logbooks, waiting for a temporary badge to be found, and observing lax security. All this will create a lasting impression of poor organization and weak security culture.

Time tracking. Access control. Safety management.

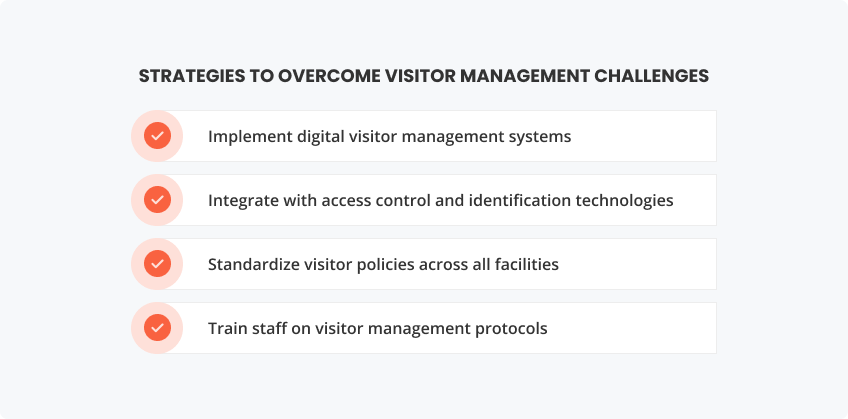

Strategies to Overcome Visitor Management Challenges

To strengthen visitor management, manufacturing companies can take proactive measures.

Implement digital visitor management systems

A digital system streamlines the check-in and check-out process. Your guests can pre-register online or register themselves on-site on a kiosk, tablet, or touchscreen monitor and enter their details or scan an ID instead of writing in a physical logbook. This helps eliminate illegible handwriting and human error, ensuring that all records are accurate and updated in real time. Digital check-in is also faster– no more long waits at the front desk – and data is stored securely in a central database.

Integrate with access control and identification technologies

Digital VMS can be integrated into the current security infrastructure and grant access based on the specific visitor’s profile. Integration means that when guests check in, the system automatically produces a time-limited access badge that only opens authorized areas. For example, a delivery driver’s badge will only unlock loading dock doors, while a vendor’s badge grants access to the designated machinery area.

Standardize visitor policies across all facilities

If your companies are located at multiple sites, don’t forget to develop a unified visitor management policy. Different protocols breed mistakes – one site might allow visitors who have no badges, while another is strict. This inconsistency creates confusion and risk both for your guests and employees. To prevent this, manufacturers should ensure core procedures that apply to every location, with some site-specific flexibility in mind.

Train staff on visitor management protocols

A VMS and its features will be much less effective without proper training for the team. All relevant personnel, such as receptionists, security guards, and site managers, should be educated on visitor safety protocols and know how to use the digital tools to navigate the registration of all visitors, including contingent workforce, full-time employees, vendors, and clients. Training should cover such topics as how to verify credentials, what the sign-in steps are, how to handle unexpected situations, and emergencies.

Benefits of Modern Visitor Management Solutions

Digital visitor management solutions bring a host of benefits.

Streamlined check-in processes and reduced wait times

Automated check-in speeds up the sign-in experience and reduces congestion at the entrance points. Guests can pre-register online or use self-service kiosks or tablets to sign in within seconds. A VMS with options such as QR code check-ins cuts front desk bottlenecks and wait times. Since the system handles registration, front desk specialists also save their time, as they no longer need to manually log each guest or repeatedly answer the same safety questions.

Enhanced security and controlled access

Visitor management system integration ensures that only an authorized person can enter the premises. It provides better control over visitor flow and replaces the uncertain “open door” of paper logs with verifiable identity checks. The system screens all guests and issues badges that restrict their movement, which reduces the chances of unauthorized wandering.

Improved compliance with regulatory standards

Consistent use of a VMS helps meet obligations under OSHA guidelines, ISO certifications, C-TPAT, and other standards. In case of inspection, managers can quickly produce detailed logs to demonstrate compliance. For example, if an OSHA inspector asks for proof that all guests receive a safety briefing, you could pull a report from the system with the confirmation that each person has signed the acknowledgment form.

Comprehensive reporting and audit readiness

Thanks to robust reporting and analytics features, it’s easy to generate reports on who and when visited the facility. Managers can easily download reports on who visited and when, identify the frequency of vendor visits, peak visitor hours, etc. Automated time-stamped records create an audit trail that is difficult to falsify.

Conclusion

Visitor management might once have been an afterthought, but today it is mission-critical. Inconsistent manual visitor management practices pose serious challenges, from inefficiencies and lack of oversight to security loopholes, compliance risks, and safety hazards. Proactive visitor management is essential in manufacturing: it safeguards your people and property, keeps you compliant, and upholds your reputation.

FAQ

Manual visitor management is inefficient and prone to error. Manual logs are easy to bypass; anyone could sign a fake name or simply walk past an unattended sign-in book. With paper-based systems, it’s difficult to maintain a complete and accurate record, which can result in compliance violations and penalties.

For improved visitor tracking in manufacturing facilities, every visitor’s entry and exit is logged electronically with timestamps, so you have an accurate, up-to-the-minute record of who is on-site. To provide compliance in manufacturing environments, digital systems ensure that required information is captured and stored for each visitor. All of this data is easy to retrieve for audits or reports.

A robust VMS should include several key features tailored to safety and efficiency needs:

- Digital check-in and identification

- Pre-registration capabilities

- Manufacturing access control integration

- Visitor screening and watch lists

- Safety and compliance workflows

- Reporting and analytics

Visitor management systems reduce bottlenecks at entry points and ensure that guests can achieve the goal of their visit without unnecessary delay. An effective system reduces the likelihood of confusion or mistakes that can disrupt operations. Fewer security incidents and compliance issues also prevent operational chaos.

Yes, visitor management systems can integrate with a variety of existing security tools. Most common integrations are with access control systems, ID badge printers, and scanners. You can also tie your VMS into the watch list databases or security platforms to detect persons who are on government denied-party lists, internal HR ban lists, or even TSA/Interpol databases. Other possible options include connection with CCTV or video management software, messaging, and emergency notification systems. An advanced VMS might be part of a larger Physical Identity and Access Management (PIAM) framework that coordinates with corporate databases, contractor management systems, and background check services.