Key Facts

- Factories’ weak link is visitor flow. Even with fences and CCTV, paper logs and inconsistent ID checks at entrances leave manufacturing sites exposed to unauthorized access and safety incidents.

- Digital VMS replaces clipboards and adds control. A visitor management system enables mobile/kiosk check-in, real-time “who’s on site” visibility, and auto-issued temporary badges/QRs restricted to approved areas.

- Compliance gets easier with audit-proof visitor tracking. Digital real-time visitor logs support OSHA/ISO 45001 requirements for controlled access and record-keeping, while GDPR-aligned data handling protects visitor privacy.

- Digital signage is a live safety channel. Screens deliver PPE reminders, wayfinding, restricted-area warnings, and instant emergency alerts — triggered by sensors/cameras for faster, clearer response.

- Integration multiplies benefits. Unifying VMS, access control, and signage enables one dashboard, automated notifications, fewer manual tasks, better situational awareness, quicker incident response, and a smoother experience for all visitors.

Modern factories are complex, high-risk environments where people, machines, and materials move constantly. Perimeter fences and cameras may be of help, but the weak link is often the front desk and paper-based visitor processes. This article explores today’s most common vulnerabilities and how digital visitor management, industrial access control, and digital signage work together to close the gaps.

friendlyway will create a tailored solution to keep everyone in your manufacturing facility safe.

Security Challenges in Modern Factories

Due to their scale, valuable assets, and the presence of both people and heavy machinery, manufacturing facilities face unique security challenges. For manufacturers, a lapse in security can lead to stolen materials, safety incidents, or costly downtime.

Common vulnerabilities in manufacturing environments

Manufacturing plants are often expansive with numerous access points, making unauthorized entry a remaining concern. Lots of facilities still rely on paper sign-in sheets and outdated logs that are easy to forge. Other weak points include a lack of surveillance in back areas, inadequate ID checks at reception, and inconsistent badge systems across different buildings.

If unauthorized visitors wander into a sensitive production area, they could unintentionally spark an accident or deliberately sabotage operations. There have been cases when untrained visitors stepped into forklift paths, causing injuries and damage. Reputational damage is another aggravating concern — if clients or employees feel the facility isn’t secure, it erodes their trust.

Compliance requirements for industrial sites

Factories should be compliant with strict safety and security regulations. In the US, according to OSHA guidelines, it is recommended to establish visitor sign-in/out procedures and detailed visitor logs. On the global level, standards like ISO 45001 (occupational health & safety) require organizations to control access to the workplace and maintain records of visitors. Since visitor logs contain personal data, they should comply with GDPR to ensure better data protection.

The Role of Visitor Management in Factory Security

Even if your manufacturing facility is protected with strong perimeter fences and cameras, a factory’s front desk is the weakest link in case visitor processes are lax. This is the problem that modern visitor management can solve.

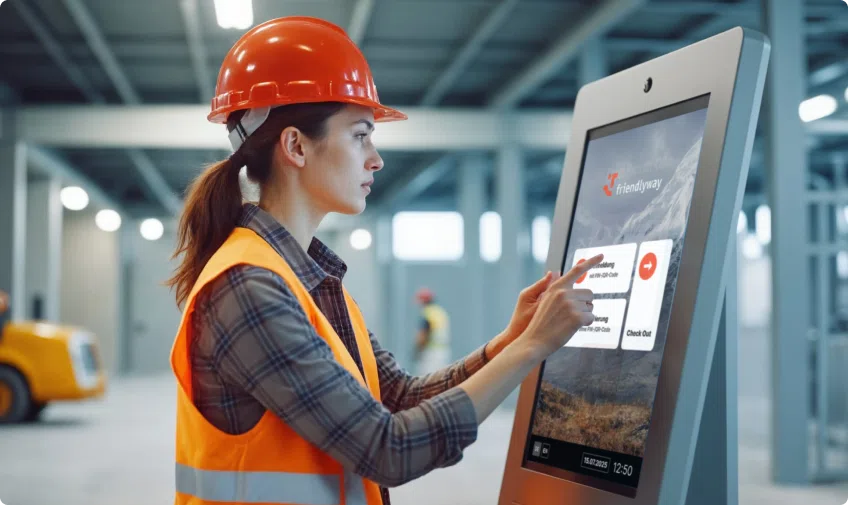

Digital check-in for contractors, drivers, and guests

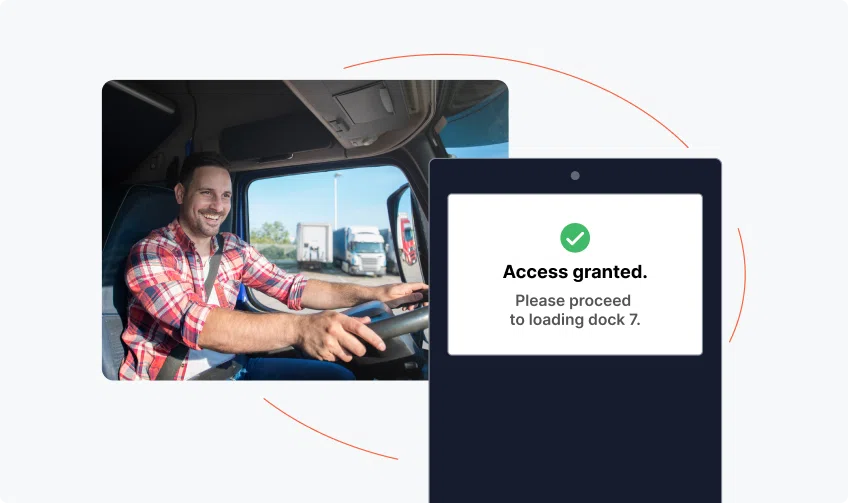

Modern visitor management starts with digital check-in processes that effectively replace the clipboard and pen. For example, at large logistics hubs, truck drivers no longer need to leave their cabs and wait in line to sign paperwork. With a mobile-enabled VMS, they can complete the entire check-in from the comfort of their truck. They just need to access a web portal or QR code on their phone and enter their details or scan their IDs.

Real-time visitor tracking and access control

With a paper log, it’s virtually impossible to know at a glance which visitors are still in the building. In contrast, a digital system shows an up-to-the-minute dashboard of all active visitors. Digital visitor management also often ties into digital access control systems. When a visitor checks in, the system automatically issues a temporary badge or QR code that grants access only to specific areas.

Audit trails and data for compliance

Every action in a digital visitor system is being logged. This creates a rich audit trail that serves multiple purposes. First and foremost, if a security incident or theft occurs, investigators can quickly retrieve records of who was on site, at what times, and where they went. Audit trails are also a boon for compliance and regulatory audits.

How Digital Signage Supports a Secure Environment

While visitor management keeps track of who is on site, industrial security signage focuses on what everyone needs to know while they’re there. In an industrial setting, digital displays are far more than just electronic noticeboards — they are active onsite safety communication tools.

Displaying safety instructions and emergency alerts

Instead of static posters that might get outdated, digital screens can show rotating content like required PPE reminders, safe operating procedures, or real-time incident tallies (e.g., “5 days since last injury”). Digital signage in manufacturing shines during emergencies: when every second counts, clear communication can be truly life-saving.

Visitor guidance and restricted area warnings

When visitors arrive, dynamic signs can guide them on where to go (and where not to go) with the help of wayfinding. For instance, a lobby display might welcome guests by name and direct them to their final destination. Equally important, digital signs can delineate restricted zones and issue automatic warnings: a screen outside a high-voltage area can display “Authorized Personnel Only — RFID Badge Required Beyond This Point”.

Integration with cameras and sensors

If an environmental sensor detects a hazardous gas leak in a chemical plant, it can trigger an immediate alert on all relevant screens: “Gas Leak in Sector 3 — Evacuate to Assembly Point B.” Advanced security cameras with analytics can detect unusual behaviors (like someone entering a restricted zone) and then trigger a connected digital sign to display a message or alarm.

Integration of Systems for Maximum Efficiency

Bringing together visitor management, access control, and digital signage into a unified ecosystem can transform your factory security from a patchwork of tools into a well-oiled automated machine.

Connecting visitor management with access control and signage

As soon as a visitor is signed in and approved in the VMS, the system automatically issues an access credential with the appropriate permissions. For example, if a contractor is only authorized for the engine assembly area, the system ensures their badge will unlock only the doors leading to that area.

Centralized monitoring via a unified platform

Rather than juggling three different screens — one for CCTV, one for the visitor log, and one for digital signage controls — security officers could have a single dashboard that aggregates all information and controls. For example, in logistics zone access monitoring, security staff can get situational awareness at a glance, which helps them correlate events quickly — if an alarm goes off at a certain door, they can see instantly that an unauthorized badge was just used there by a specific visitor.

Automation of manual tasks for security teams

Think of all the manual activities that relate to traditional visitor management and communications: filling out visitor badges by hand, emailing teams when a contractor arrives, updating paper bulletin boards with the latest safety news, etc. When all systems are unified and digitized, all these activities can happen automatically in the background without the necessity of human interaction.

Streamline communication and improve safety with a best-in-class platform.

Benefits for Manufacturing Companies

Investing in an integrated visitor management and digital signage solution isn’t just about avoiding worst-case scenarios — it actively improves day-to-day operations.

Increased situational awareness

Integrating visitor management and signage gives real-time situational awareness that wasn’t achievable with older methods. Thanks to dynamic displays, security personnel know who is on site and where, and employees on the floor are aware of what is going on around them at any given moment in time.

Improved incident response

In manufacturing companies that use these technologies, response to any incident becomes more organized, data-driven, and rapid. When something does go wrong — be it an injury, equipment failure, or security breach — early detection and alerting through connected sensors and signage ensures it is noticed immediately. Fast notification means quicker reaction times and more efficient rescue or containment actions.

Higher visitor satisfaction and lower operational risk

Interestingly, the same systems that boost security can also lead to happier visitors and smoother operations, which is a win-win for the company. All visitors, be they delivery drivers, contingent workforce, or VIP guests, appreciate a streamlined, professional experience.

From the company’s perspective, these improvements translate into lower operational risk and cost: when visitors follow the rules and stay informed, there are fewer accidents and disruptions.

Case Studies and Applications

To ground these ideas in reality, let’s delve into a few scenarios where integrated visitor management and digital signage are making a difference. From logistics hubs to high-risk industrial plants, these case studies are bright examples of how the concepts we’ve discussed come to life on the factory floor.

Secure check-in for truck drivers at logistics hubs

Scenario: A large manufacturing campus has dozens of trucks arriving daily to deliver raw materials and pick up finished goods. Traditionally, drivers would park, walk to a security office, sign a clipboard, and wait for instructions. This cumbersome process caused backups and sometimes security blind spots.

Solution: The facility implemented a digital visitor management system that was specifically configured for logistics purposes. Now, as soon as drivers pull up to the gate, they see a sign with a QR code or a short URL. With the help of their smartphone, drivers complete the check-in process without leaving their cab.

Real-time communication in chemical or high-risk areas

Scenario: A chemical manufacturing plant handles hazardous materials and operates complex processes where quick communication is vital. The facility is noisy, spread out, and workers do not carry mobile phones due to safety rules. Traditional alarm sirens exist, but without clear information, workers have trouble with quick response during emergencies.

Solution: The plant installed a network of digital signage screens across all production and common areas. On a normal day, these screens show helpful content: the day’s safety focus, reminders about wearing respirators in certain zones, and key production stats. In case of an emergency, such as when a toxic gas leakage happens, the digital signs instantly flash a warning and display evacuation routes away from the contaminated zone.

Digital briefings for maintenance personnel

Scenario: An automotive parts factory regularly brings in outside maintenance crews for equipment servicing and repairs. Previously, every contractor had to be individually briefed by a supervisor about the manufacturing facility safety rules. This was time-consuming and sometimes inconsistent — if a supervisor was busy, contractors might wait or receive a rushed briefing.

Solution: The factory leveraged its visitor management and digital signage system to create an automated digital induction process for maintenance visitors. Now, when contractors arrive for a scheduled job, they sign in at touchscreen check-in kiosks. The system immediately plays a short, tailored safety briefing video.

Conclusion

When visitor management, access control, and digital signage operate as one system, factory security reaches new levels. By addressing physical vulnerabilities such as unauthorized access and lack of oversight and improving communication, these technologies create a safer, more efficient industrial environment.

Just as importantly, they help manufacturers comply with stringent safety regulations, turning security into a source of confidence rather than anxiety during audits or client visits.

FAQ

Yes, a VMS not only improves security but also creates the documentation and controls needed to meet various regulatory requirements, from tracking who’s on site to proving that all safety protocols are properly communicated and enforced.

Digital signs centralize your communications so that the right information is shown at the right place and time. Thanks to clear, consistent messaging — from emergency alerts to everyday guidance — digital signs ensure that communication breakdowns, which can lead to safety incidents and confusion, are minimized on site.

Absolutely. Most modern visitor management and digital signage solutions are designed with integration in mind, using APIs or built-in connectors to work with your existing systems. For instance, a visitor management system can integrate with your electronic access control system (door locks, turnstiles, badge printers) so that visitor badges are automatically programmed to grant appropriate access.

Digital visitor management platforms employ several measures to keep personal information safe. Encryption is one: data like names, IDs, and photos are encrypted in transit and at rest, so even if someone intercepted the data, it would be unreadable. Access to visitor records is typically restricted by user roles. Good systems also allow you to configure data retention policies. You might set the system to automatically purge visitor records after, say, 90 days (or whatever period compliance requires) to avoid keeping data longer than necessary.

The hardware needed is relatively straightforward and often minimal. For a visitor management system, you’ll typically need a device for manufacturing site check-in — commonly a tablet or a touch-screen kiosk at your reception or gate. If you have multiple entry points, you might deploy a tablet or kiosk at each of them.