In manufacturing environments, effective communication can dramatically impact productivity and safety. Traditional methods like bulletin boards and printouts often fail to keep factory teams informed in real time. Read on to find out how digital signage in manufacturing addresses challenges in plant communication – from production dashboards to emergency alerts and more.

Streamline communication and improve safety with a best-in-class platform.

Why Digital Signage Is Ideal for Manufacturing Environments

Manufacturing facilities can be hectic, noisy, and ever-changing, which makes communication difficult. This section explores why digital signage is an ideal shopfloor communication tool and how it outperforms old-fashioned bulletin boards.

Challenges in internal communication on the shop floor

Factory workers often don’t have easy access to email or computers during shifts, which makes it hard to disseminate critical information between teams. Digital signage tackles these issues by sending messages in a consistent, visual format that is accessible to everyone.

The need for real-time, visual information

Workers and supervisors need current data that is available at a glance – whether it’s the latest output count or an urgent safety alert. By placing large factory floor display screens in strategic spots such as production lines, break areas, or entry points, plants create a unified information channel.

Benefits over traditional bulletin boards and paper signage

Many plants still use old-fashioned paper postings because “that’s how it’s always been done.” Nevertheless, digital signage outclasses traditional bulletin boards on multiple fronts: it is easier to update and helps to reduce clutter and paper waste. Moreover, with features like content rotation and split-screen layouts, a single digital sign can deliver the equivalent of multiple bulletin boards’ worth of information.

Use Case 1: Real-Time Production Dashboards

Modern factories are data-driven, and real-time KPI displays have become game changers for boosting productivity. Let’s discuss how digital signage systems serve as live production dashboards.

Displaying KPIs, output metrics, and line performance

Digital signage transforms raw production data into visible goals and feedback for teams. Large industrial digital displays can display metrics such as units produced, defect rate, and alarms directly from the MES system dashboards.

Live updates from MES or ERP systems

Factories can integrate digital signage with Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) software, and other databases to automatically populate screens with up-to-the-minute data.

Line-by-line visibility for supervisors and staff

Before digital dashboards, supervisors and staff used to walk the length of a production line with a clipboard to gauge performance. Now each production line or cell can have its own screen highlighting that line’s specific metrics and any issues.

Use Case 2: Safety Alerts and Emergency Communication

Nothing is more important in a plant than safety. This section explains how digital signage serves as factory safety signage to enhance emergency communication.

Visual alarms for fire, gas leaks, and lockdowns

When an emergency strikes, every second counts. For example, in case of fire, gas leak, or the lockdown, all networked screens across the facility can automatically switch to a bold evacuation message with flashing lights to catch the attention of employees.

Automated messaging during incidents

Manufacturing plants can integrate digital signs with their emergency notification systems. For instance, if a fire sensor or gas leak detector goes off, it can directly send a signal to the signage CMS to display the relevant emergency protocol on all screens without waiting for human input.

Integrating signage with safety systems and sensors

For maximal impact, digital signage should be part of the broader safety infrastructure of a plant. Many factories link their IoT sensors and alarm outputs to digital signage controllers, so when an alarm is pulled or a safety system is triggered, the screens respond in tandem.

Use Case 3: Shift Schedules and Workforce Communication

Digital signage is a reliable tool that helps manufacturing plants broadcast shift-specific info in real time. These shopfloor communication tools keep the workforce informed, which improves transparency and morale.

Digital rosters and break schedules

Digital signage displays show who is on shift, where they’re assigned, and upcoming break or rotation schedules on screens that workers naturally pass by. For example, a large monitor might show “Today’s Line 1 Team” listing each operator’s name and role, plus any job rotations or breaks scheduled for that day.

HR updates and internal announcements

Factories have important internal news just like any other organization – new policies, benefit updates, training sessions, HR events. Communicating these to production workers is not a challenge anymore – with digital signage, it’s easy to disseminate information across digital screens.

Personalized messages for departments or roles

You can send targeted messages to specific screens or groups of screens. This way, each team sees only the content relevant to them. For example, in the Quality Control lab, the display might show QA metrics, calibration schedules, and quality alerts, while the Logistics area’s screen shows delivery schedules and dock assignments.

Use Case 4: Training and Standard Operating Procedures (SOPs)

Digital signage offers an engaging way to carry out training and SOPs. Think of it as micro-training activities that are delivered directly to the employee’s workplace.

Visual guidance for new staff or rotating teams

With digital signage, factories can dramatically shorten the learning curve by providing visual work instructions. For instance, a screen at a workbench could display a step-by-step walkthrough of how to assemble a component or perform a setup.

Instructional loops on best practices and safety

Repetition is key to learning and habit formation. For example, during each shift changeover, the screens in the break area might run a 5-minute loop that includes reminders like how to properly lockout-tagout equipment, the correct lifting technique to avoid injury, or key steps from the quality checklist.

Multi-language and accessible format

In just a few clicks, it is possible to duplicate a message in multiple languages. For instance, a safety rule like “Wear ear protection in this area” can alternate between English, Spanish, and French on the same display, or appear on different displays in different languages depending on the predominant language of workers in that area.

Use Case 5: Quality Control and Compliance Messaging

Ensuring consistent product quality and meeting regulatory compliance requires constant attention from everyone in the plant. Here, we discuss how digital signage helps uphold these standards.

Displaying checklists and compliance updates

A screen in an assembly area might, each hour, highlight one step from the quality inspection checklist (“Did you verify torque on all bolts? Check now.”) in the form of a pop-up message. Another neat use is showing countdowns towards compliance goals: if the site needs to complete 100% of safety training by a certain date, a display could show a progress bar “Safety Training Completion: 85%” to motivate employees to finish.

Real-time alerts for deviations or audit events

If defective parts are detected on the production line, a screen at the team lead’s station could flash “QUALITY ALERT: Line 2 high defect rate – check process!”. Similarly, if an internal audit finds an issue, the relevant team can be informed so that they can address it promptly.

Reinforcing ISO or OSHA protocols visually

A digital display can show key performance indicators tied to quality objectives, reminding everyone of targets to meet ISO protocols. Similarly, a safety on-screen dashboard might display safety training compliance rates and graphical reminders of required PPE to reinforce a safety-first culture compliant with OSHA standards.

Use Case 6: Logistics and Loading Dock Coordination

Digital signage brings real-time coordination and information flow to logistics, ensuring high transparency and efficiency.

Coordinating inbound/outbound delivery slots

Digital signage streamlines inbound/outbound delivery with real-time schedules and updates for both staff and drivers. For instance, a large outdoor LED display could list upcoming delivery slots: “10:00 AM – Truck #1234 (Supplier XYZ) -> Dock 4”. This way, arriving drivers immediately know where and when to go, reducing truck wait times and minimizing congestion.

Queue and bay assignment displays

Another tangible improvement comes from using digital signs to manage truck queues and bay assignments. Imagine arriving at a factory gate and seeing a digital marquee that says “Truck ABC123: Proceed to Gate 5” – that level of clarity immediately sets the driver on the right path. Once on site, digital bay displays can then guide the driver to the exact bay. For example, a screen might indicate: “Dock 7 – Receiving for PO #456 (Flashing when it’s this truck’s turn).”

Driver instructions and area-specific alerts

A digital board at the entrance might display instructions for drivers: “Welcome! Park in Lot B and wait for your dock assignment. PPE required beyond this point.” Area-specific alerts are crucial in case of hazards: a digital sign at the entrance could flash “Caution: Spill cleanup at Dock 3, expect delay” so incoming drivers know to avoid that area.

When you enter a large manufacturing plant for the first time, it can be a really intimidating experience – there are so many safety rules to learn, specific areas that are hard to find, and often a complex sign-in procedure. Digital signage can serve as a friendly concierge to make visitor management a pleasant experience for employees and visitors alike.

Welcome messages and orientation videos

When a vendor or client arrives, a digital welcome board might display a personalized message: “Welcome, John Smith from XYZ Corp!” Then, a screen in the reception might say “Before proceeding, please watch the 3-minute safety orientation video”, in which the system will show key points like PPE requirements, emergency alarms, and restricted zones.

Wayfinding to safety zones, meeting rooms, or equipment

A touchscreen in the lobby might let someone select their destination (e.g., “Conference Room B” or “Packaging Department”). Then, it will display a map with the highlighted route. There are also options for sending direct notifications to the phone via QR code.

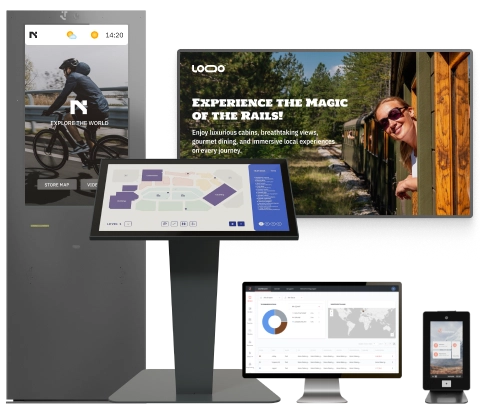

Integration with self-check-in kiosks

Many factories now use self-service kiosks at reception for streamlined visitor management. Self-service kiosks powered by touchscreen monitors handle sign-in, NDAs, and badge printing.

Use Case 8: Energy and Sustainability Monitoring

With the help of digital monitors, companies can display emissions, recycling, and energy-saving metrics they’re working toward.

Displaying energy usage and targets

Many factories have energy management systems (EMS). These systems track electricity, gas, and water usage. You can integrate these systems with digital displays and show current consumption levels. A screen might display “Current Power Usage: 1.2 MW” alongside a daily or monthly goal line (“Goal: 1.0 MW average”).

Live stats on emissions, recycling, and savings

It is possible to configure the screens to showcase environmental metrics. Among industrial signage use cases, you can show how much waste is being recycled versus sent to landfill, or how much the company’s efforts have reduced carbon emissions.

Motivational messages tied to sustainability goals

For long-term impact, it’s not enough to show just mere numbers. With digital signage, you can inspire your team with motivational mottos. Next to a live energy graph, the screen might also display a tip of the week: “Sustainability Tip: Compressed air leaks can waste energy – report any hissing sounds to maintenance. Let’s eliminate leaks and hit our energy goal!”

friendlyway will create a tailored solution to keep everyone safe and informed on your shop floor.

Conclusion

With digital signage, you can enhance the shop floor with a clear, real-time communication network — one place for KPIs, digital safety alerts, schedules, training, and logistics updates. Start small with a pilot on one line or area, measure the impact, and then scale its implementation across the plant for consistent, measurable results.

FAQ

Sure. Modern solutions offer the capability of manufacturing ERP integration and MES connectors on demand.

For the majority of manufacturing areas, a combination of rugged screens, high brightness output, strategic placement, and attention-grabbing content design ensures the signage is clearly visible.

In a factory environment, durable industrial-grade screens are preferable. They can handle continuous operation and rough conditions.

Absolutely. You can adjust the content based on location (department) and even schedule different content for different shifts or times of day.

Safety audits look for evidence that the factory communicates hazards, training, and protocols effectively and that employees follow safety procedures. Digital signage helps on all those fronts by keeping safety information highly visible and up-to-date for all employees.